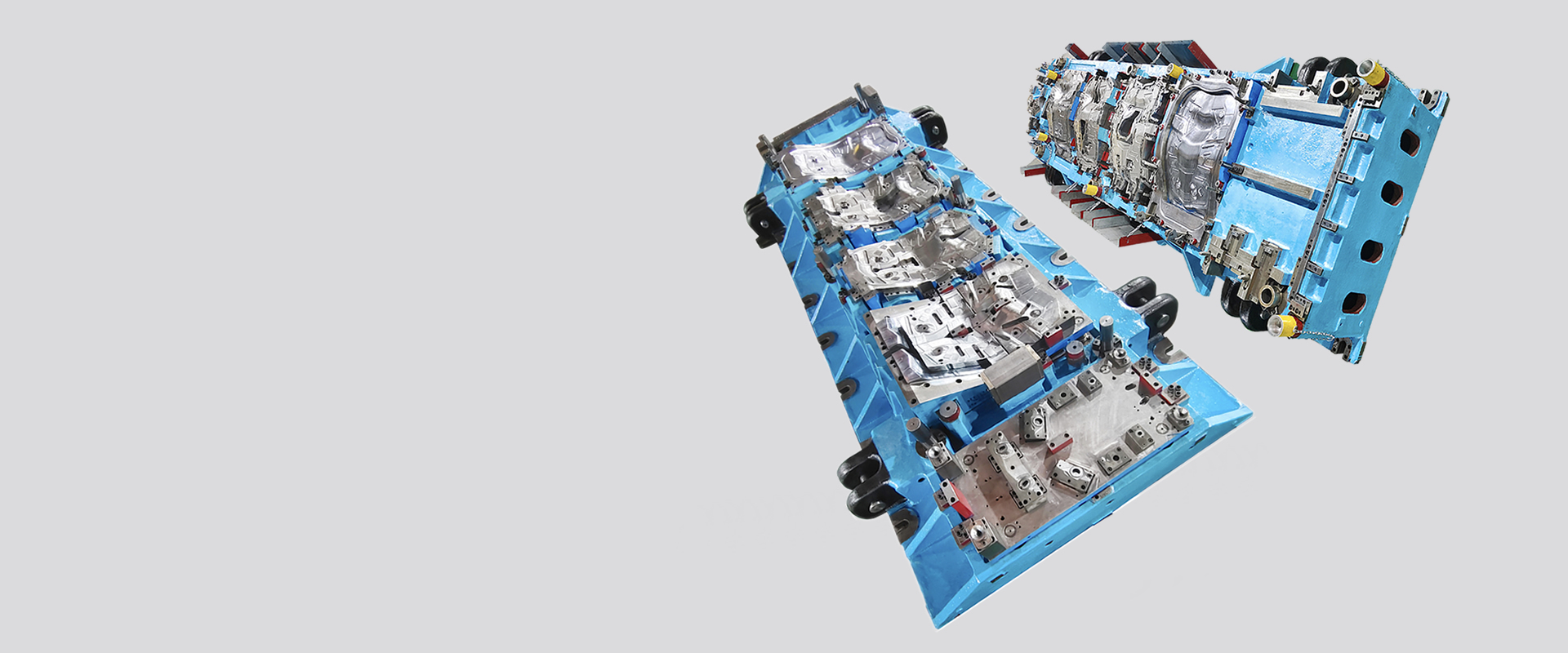

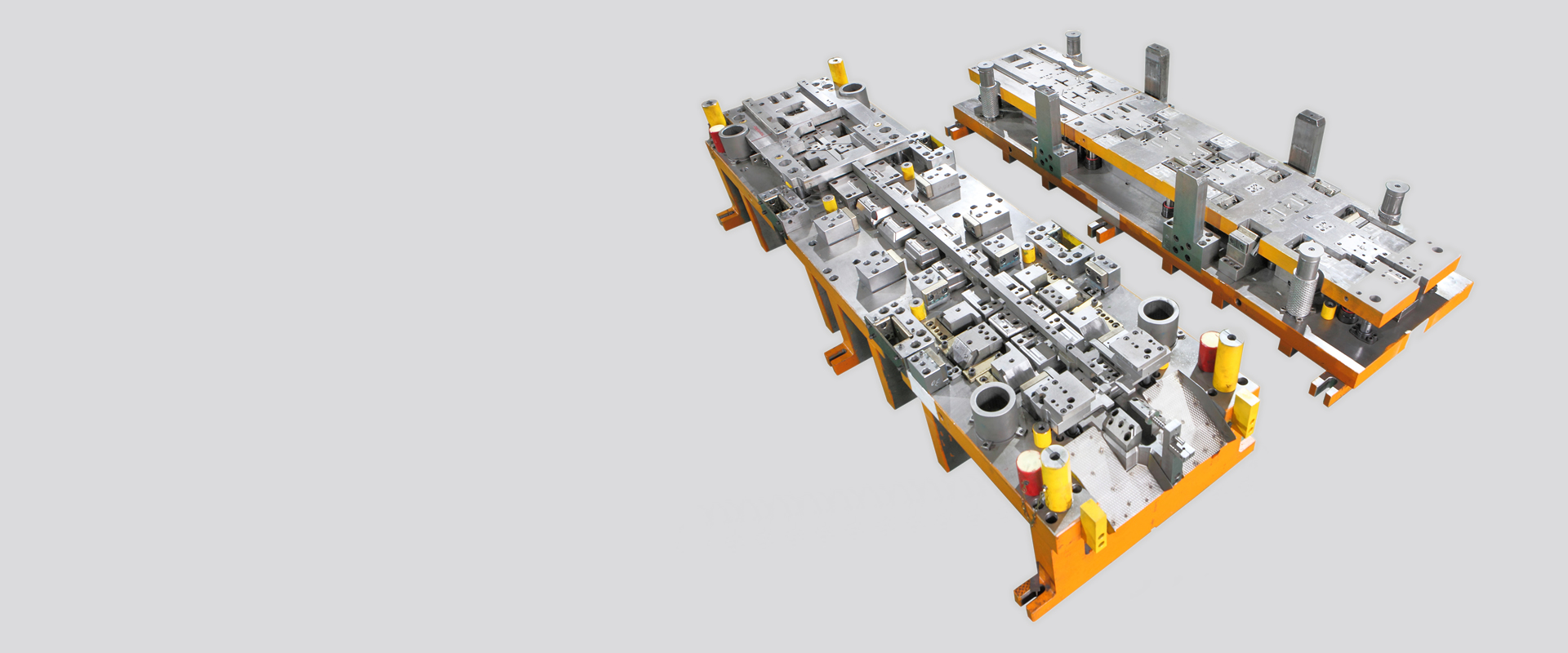

A professional tool&die maker for big progressive tools and transfer tools

From Zerostart to Unlimited Cooperation

Focus on Stamping tool&dies

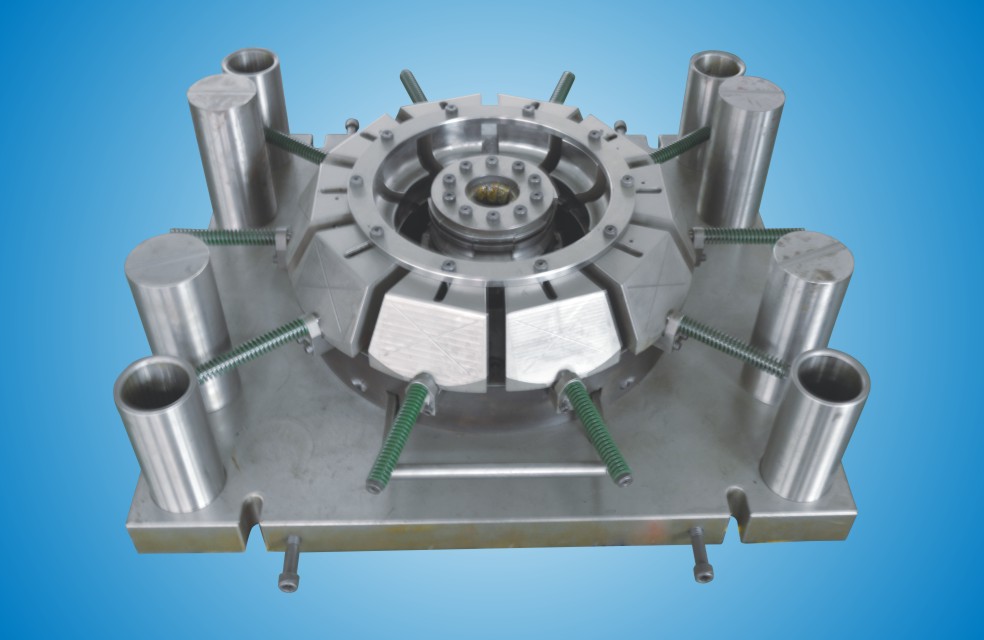

A dual color mold is a mold where two plastic materials are injected into the same injection molding machine, forming in two stages, but the product is only produced once. The two-color Injection mold construction molding needs two-color mold and two-color injection molding machine. During the production injection molding process, it is necessary to control the amount of adhesive for the first color of the injection molding. The quality of the first color product is directly related to the problem of adhesive wrapping for the second color. If the first color product is not firm, it will produce flash during injection molding. The accuracy of the mold must be ensured for two color products, as the sealing position of the product is directly a one color product.

The final speed of the two color injection molding machine must be slow. Two color mold molding is generally divided into two categories: one is mixed color and two color Injection mold construction, that is, two nozzles of the injection molding machine alternately inject materials of different colors into the same mold cavity to form decorous products without obvious boundaries; the other is double-layer and two color Injection mold construction, that is, two nozzles successively inject two materials into the bicolor products with obvious boundaries that constitute the products, and the first nozzle injects the materials into a small cavity for molding, Afterwards, the mold is opened but not ejected. After the mold rotates 180 degrees, it is closed. Then, the second nozzle injects another material into the large cavity that already has the first material. This way, the two materials stick together, and the second mold is ejected to inject a complete dual color product. However, this type of mold is divided into large and small cavities, so it is still necessary to eject the complete product every time the mold is opened. Generally, one of the two materials used in this type of mold has important assembly relationships and strict dimensional requirements, while the assembly relationships of the other material are not very important and generally only meet the requirements of decoration, cushioning, or texture. Therefore, this layer of material is usually placed in secondary injection molding. This type of mold is also commonly used in the past, where two sets of molds are opened and one material is used first, Afterwards, insert him into another set of molds and inject another material.

The injection molding machines for double-layer and two-color molds are all rotary injection molding machines, which fix the mold on a rotating disc and rotate the mold 180 degrees every time the material is moved. The two nozzles of this injection molding machine are arranged horizontally and up and down, and the maximum injection amount of the two nozzles is larger and smaller. This must be noted during design, Otherwise, if the cavity with a large amount of material is incorrectly placed on the nozzle with a small injection amount, it may result in insufficient injection amount, and the mold may be scrapped. During the process involving this type of mold, it is necessary to always pay attention to its rotation of 180 degrees to smoothly close and open the mold.

info@zerostart-tool.com

No.525,Jinxing Road FuShan Village LiaoBu Town,DongGuan city,GuangDong Province,China

(86-769)81008391

Online service

Website QR Code