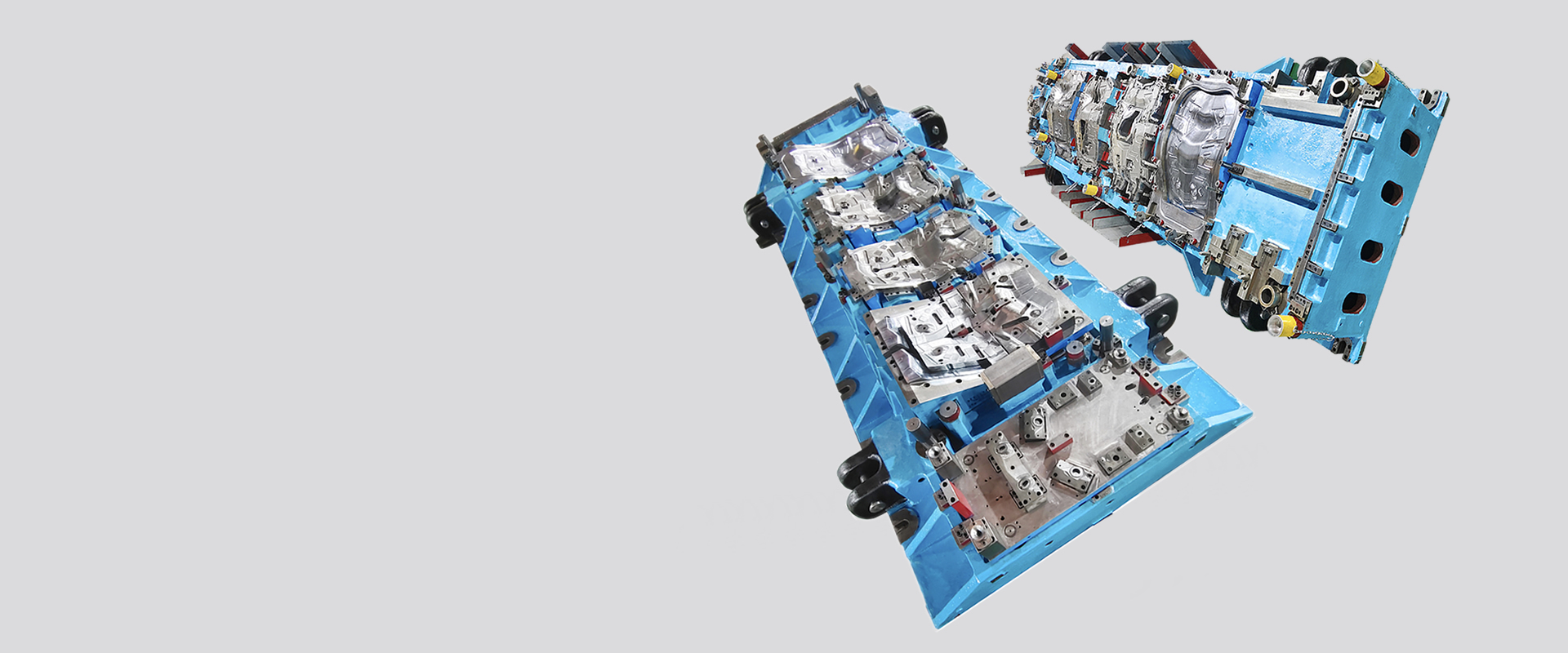

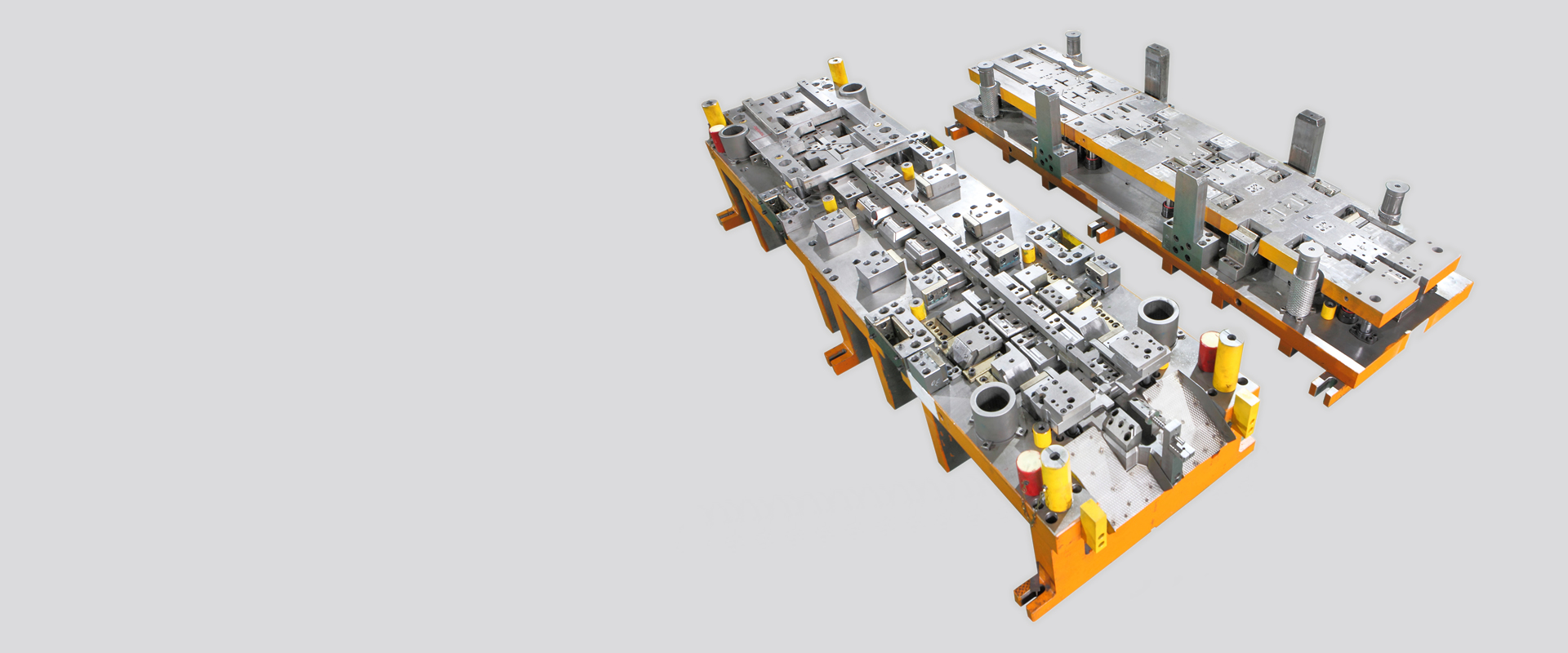

A professional tool&die maker for big progressive tools and transfer tools

From Zerostart to Unlimited Cooperation

Focus on Stamping tool&dies

As a leader in the mold industry, the quality of the dual color mold equipment will directly affect the quality of the product. Moreover, the cost of dual color molds during injection molding is significant, and their lifespan also affects the cost of plastic products. So, maintaining the dual color mold well can greatly reduce costs and increase product quality.

Before using the dual color mold:

1. Treat the rust and oil stains on the dual color mold equipment and check if there are foreign objects blocking the cooling water holes.

2. Check if the arc of the mold adhesive sleeve is damaged and if there is any residue.

3. When the dual color mold is running, it is necessary to run the empty mold and check if all parts are in good condition.

Dual color mold in use:

1. When using a dual color mold, it is necessary to maintain a normal temperature and avoid sudden changes in temperature, in order to extend the lifespan of the dual color mold.

2. Check all parts of the mold every day for damage, and regularly inspect and maintain them every day. If there are problems, they must be replaced.

3. Regularly check whether the water channel of the mold is smooth, tighten all screws, check whether the limit switch of the mold is abnormal, and whether the inclined pin and inclined top are abnormal.

After using the dual color mold:

In order to extend the service life of the dual color mold, after use, use an air gun to remove foreign objects from the water channel hole, add a small amount of engine oil to the nozzle, and then blow it away with an air gun to achieve a layer of rust resistant oil layer.

2. In addition to handing over production and some important tasks, colleagues on the morning and evening shifts should also provide detailed explanations on the use of dual color molds.

3. If the machine is turned on after a temporary shutdown, check if the sliding position has moved after opening it. Only if no problems are found can the mold be closed. In short, be extremely careful before starting the machine.

If the dual color mold is used up, a mold library should be established and the dual color mold should be placed in a place without moisture or ventilation. If the humidity exceeds 70%, the dual color mold is prone to rust.

info@zerostart-tool.com

No.525,Jinxing Road FuShan Village LiaoBu Town,DongGuan city,GuangDong Province,China

(86-769)81008391

Online service

Website QR Code